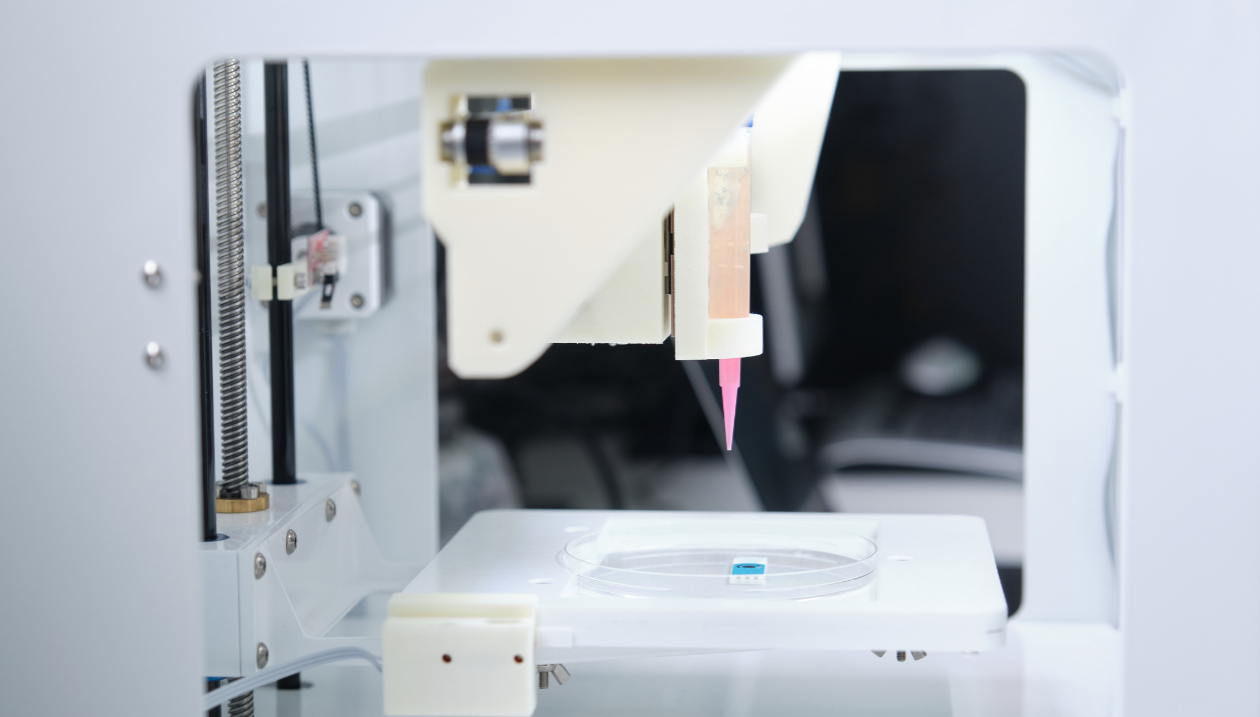

From joint pain to degenerative diseases like osteoarthritis, cartilage injuries are among the most common and difficult to treat. Traditional solutions often involve invasive surgery or cell therapies with limited long-term results. But what if we could simply print replacement tissue? That’s the vision behind Olivia Steiner’s biomedical engineering research at the University of Ottawa. Her work focuses on bioinks — 3D-printed living tissues — and how to improve them.

Engineering better bioinks

Bioinks are essential to the growing field of 3D bioprinting, but they come with a host of technical challenges. “There are still many difficulties in developing bioinks that have the right consistency and behaviour to reliably print tissue while also supporting cell health,” explains Steiner.

Her goal? To improve bioinks — the gel-like materials used in 3D bioprinting — by testing a new way to strengthen them before printing.

Steiner uses a technique called pre-crosslinking with alginate, a compound derived from seaweed. Over the course of her research, she analyzed over 100 different ink formulations, testing how small chemical changes could improve print quality and cell viability. The results were promising.

“Our modifications didn’t just change the ink’s material properties. In some cases, they actually made it easier to print precise tissue structures while preserving an environment that supports healthy cell growth” says Steiner.

Potential applications in regenerative medicine

This breakthrough has far-reaching potential. While Steiner’s work centers on cartilage, the techniques she’s developing could be applied across the broader field of biotherapeutics and tissue fabrication.

Looking ahead, she hopes this research will support the creation of personalized implants that mimic the structure of native cartilage, offering less invasive alternatives for people with cartilage lesions or early-stage osteoarthritis.

“These kinds of constructs could one day be used as implants to repair damaged cartilage, which would be a major improvement over current treatment options,” says Steiner.

Collaboration at the heart of innovation

Steiner’s research was conducted under the supervision of Dr. Jean-Philippe St-Pierre, with hands-on support from her lab team and collaborators from the Bio-nanomaterials Chemistry and Engineering Laboratory, who provided technical insight and equipment expertise. “Biomedical engineering is such a multifaceted field,” Steiner notes. “It really encourages us to learn from each other’s unique expertise.”

Her next challenge? Taking the bioinks even further. She aims to optimize them for the development of osteochondral constructs — 3D-bioprinted tissue that mimics both cartilage and bone, with the long-term goal of supporting joint repair.

As she looks ahead, Steiner is committed to staying in research and development. “I find biofabrication incredibly inspiring,” she says. “I want to help bring these technologies to the clinical stage, where they can truly make a difference in people’s lives.”

Designing and developing new materials and processes, a uOttawa Engineering priority

Olivia Steiner was awarded first place in the Emerging materials and processes category at the 2025 Engineering and Computer Science Graduate Poster Competition held during Engineering Research Celebration Day at the Faculty of Engineering.

Steiner’s project aligns with the Faculty of Engineering’s research priority in Emerging materials and processes, focusing on innovations that improve health outcomes and support personalized medicine.