Dialing back the chronological clock: Redefining the possible

Overview

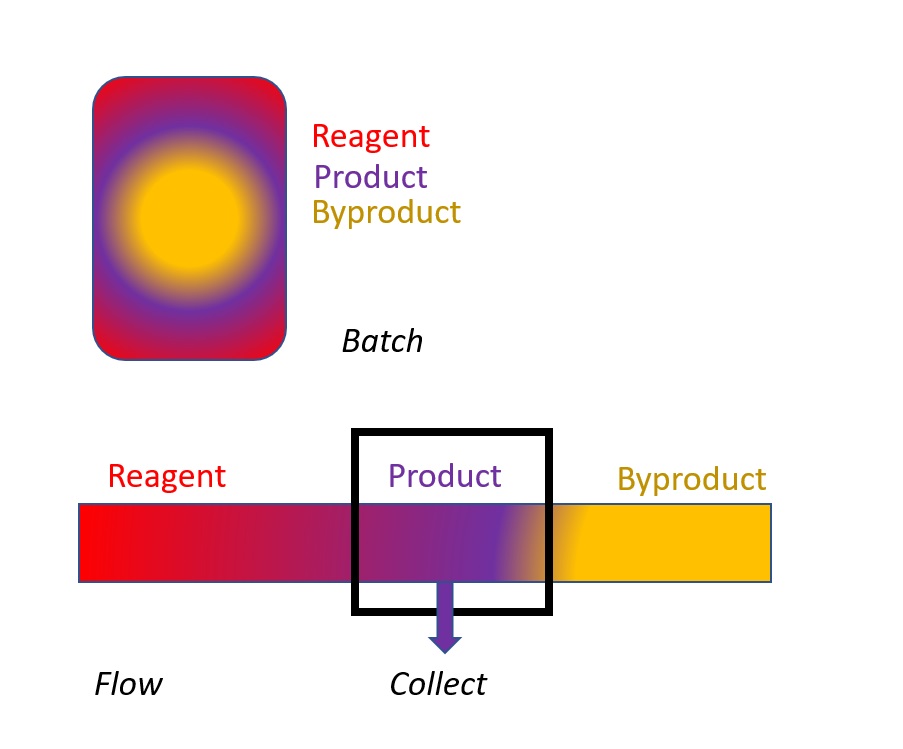

Flow chemistry enables us to perform reactions in a tube instead of in a vessel. Reagents convert into a product overtime as they continue to flow across the tube. In vessel chemistry, which we call batch chemistry, only 'bad things' (e.g., degradation) can happen to a product molecule, which has nothing to do except hang around in the sea of reagent molecules since its formation as we wait for the remaining reagent molecules to react. If we wait too long, we would likely harvest more product, but at the cost of sacrificing the quality of the product. Unfortunately, we can't clock back the reaction time once the reaction has already proceeded for a period of chronological time. The reaction clock, which is dictated by how long we let reagents stir in the confinement of a reactor, and the chronological clock, the fourth dimension of the space-time continuum where the reagents convert into the product, are inseparable in batch format. If a reaction matter is stirred too long inside a batch reactor, it's not possible to fish out the product leaving the reagent or the byproduct molecules behind. Fortunately, the flow format allows us to deconvolute reaction time into reactor length, a parameter that we modulate in both directions (i.e., letting something flow longer or draining something out quickly). As long as we have the ability to 'monitor' reactor states (i.e., the distribution of reagents and product at a given time) at any reactor length, we can make an informed decision on when to channel good products out of the reactor, or in other words, when to stop a reaction in the 'past' by seeing the reaction in the 'present'. The key is, however, to come up with a PAT that would allow us to simultaneously 'see' reactor states at multiple points across the reactor tube, take action in 'current' chronological time, and reset the reaction back to a 'past' reaction time.

The Flow Facility, in collaboration with a leading manufacturing company designed and manufactured a fluid diverter prototype (see an example 2-ring 12-port LSV on the right) that allowed this multi-point simultaneous sample extraction strategy from a pressurized flow reactor without breaching critical process parameters of the flow process during the sample extraction process. The ultimate result was the creation of a space-time reactor, which is currently being tested for an application in the area of medical diagnostic. The whole discovery stemmed from a highly coordinated collaborative research among the experts of three Canadian Universities, the manufacturing and engineering partners, and the Flow Research Facility. Click below to learn more about this multi-point sampling technique.