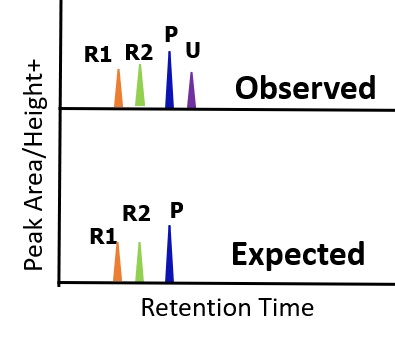

What happens when a new peak (the purple peak U) shows up! The question remains if this 'unknown' peak formed during analysis or in the process? For decades, scientists used peak spiking strategies to decide what is real and what is not. They reflected on their mechanistic expertise and experiential knowledge to infer how a particular process condition gives rise to an entity that fits the unknown ghost peak profile. And, more often than not they were right. That slow but steady rational approach, however, came at a cost, time. Making standards until the one fits the 'unknown' profile is not a routine task. It's up to the scientists to make a decision call on whether to take 'slow and steady' rational QbD approach, where the benefit of 'speed' may have to be compromised, or 'fast and risky' HTE approach, where we turn a blind eye to the devil in the details.

The Flow Facility, in collaboration with a number of LC and valve manufacturing companies stepped in to help out with this multi-attribute process intensification problem. We provided a unique multi-dimensional recirculatory platform that is exclusively designed to address the problem discussed above. More importantly, the platform eliminated the need for analytical standards and speeds up HT multidimensional process intensification for multi-attribute processes. Click below to learn more about this multi-attribute process optimization tool technique.